What Can Adhesives and Sealants do for my Bonding Solutions? – Polymix

Introduction to Adhesives and Sealants

Auto refinishing is an art that extends beyond the strokes of a paintbrush. Beneath the glossy finish lies a world of precision, where adhesives and sealants play a pivotal role in creating the ultimate bonding solutions. In this blog post, we’ll delve into the craftsmanship of utilizing adhesives and sealants in auto refinishing, exploring their applications and the finesse required to stitch together vehicles.

Adhesives: The Silent Architects of Bonding Solutions

Adhesives are the unsung heroes in the auto refinishing process. Whether mending structural damage or bonding various components together, these compounds are the silent architects that ensure the vehicle’s integrity. From metal-to-metal bonds to securing intricate parts, the right adhesive sets the stage for a flawless finish. The choice of adhesives in auto refinishing is not just about sticking things together; it’s about providing structural strength while maintaining flexibility. Modern adhesives are formulated to withstand the dynamic stresses a vehicle experiences, ensuring that the bonds remain strong under various conditions without compromising the overall flexibility of the vehicle’s structure.

How do you choose the right Adhesive for the ideal Bonding Solutions?

Auto bodies face a myriad of challenges, from dents to minor damages. Adhesives shine in their ability to address these challenges efficiently. Whether it’s repairing plastic components, bonding dissimilar materials, or reinforcing structural elements, the right adhesive simplifies the repair process, saving time and preserving the vehicle’s original integrity. In addition, selecting the appropriate adhesive is a critical decision in auto refinishing. Different surfaces and materials require specific adhesives for optimal performance. Understanding the project’s requirements, consulting with experts, and relying on reputable suppliers ensure that you choose the right adhesive for the job, maximizing its effectiveness and longevity.

How can you properly apply your adhesive?

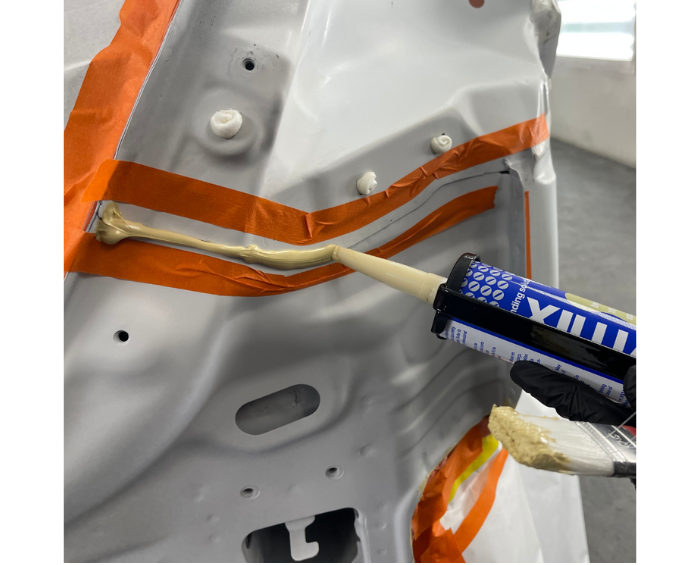

Applying adhesives in auto refinishing is an art that demands precision. Proper surface preparation, accurate measurements, and meticulous application are essential for achieving optimal results. The careful use of adhesives contributes not only to the visual appeal but also to the structural soundness of the vehicle.

Sealing the Gaps

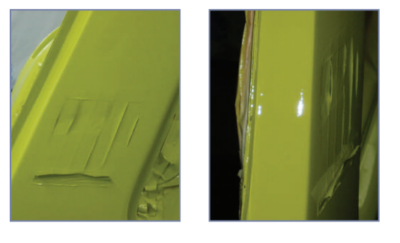

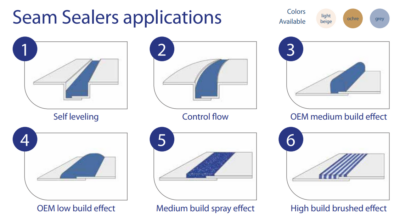

Sealants are the guardians of a vehicle’s longevity. They fill gaps, seal seams, and provide a protective barrier against the elements. Beyond enhancing the aesthetics, sealants are essential for preventing moisture, dirt, and contaminants from infiltrating vulnerable areas, safeguarding the vehicle against corrosion, and ensuring a lasting, polished appearance. Sealants go beyond aesthetics, preserving the beauty and functionality of a vehicle. From weatherproofing seams to preventing rust and corrosion, sealants are the finishing touch that ensures the refinishing work stands the test of time. Their role in maintaining the vehicle’s appearance and protecting against environmental factors is invaluable.

Available Products:

Polymix Bonding Solutions: is the modern solution to adhesive application in the ever-changing automotive industry. As car manufacturers continue to innovate with plastic and composite materials to reduce the weight of the vehicle, conserve fuel consumption, and increase safety, the industry needs to adapt. Polymix has a wide range of solutions for all of the new methods of repair.